Not known Facts About Best Dust Extractors

Wiki Article

The Best Strategy To Use For Best Dust Extractors

Table of ContentsThe 9-Second Trick For Best Dust ExtractorsSee This Report about Best Dust ExtractorsThe 30-Second Trick For Best Dust ExtractorsAll about Best Dust ExtractorsHow Best Dust Extractors can Save You Time, Stress, and Money.Not known Incorrect Statements About Best Dust Extractors The Best Dust Extractors Ideas

The CMAXX is a reverse pulse-jet cartridge dust collector. The very best method to explain what this means is to go on a tour of the path that air complies with through the dust collection system. Filthy air consisting of bits of dust goes into the collector through the ductwork. Followers either press or draw the air with the air ducts.As an outcome, this keeps the dirt from hitting the filters at complete rate. At the bottom of this room, accumulated dust drops out right into a drum or hopper.

In the CMAXX, these hang up and down from the tube sheet, which is the steel sheet separating the unclean as well as clean air spaces. This makes the spaces that the air should go through smaller.

Best Dust Extractors - An Overview

Several of it drops off. Some of it adheres to the filters. Gaskets at the top of each filter seal it to the tube sheet to keep dust from sneaking through. A pulse of pressed air strikes right into the filters. Due to the fact that the pulse of compressed air goes in the reverse direction of the normal air flow, we call it a reverse pulse-jet collection agency.The dirt goes down out of the enthusiast and also the filters are all set to accumulate even more dust. A pulse-jet enthusiast is a very reliable type of industrial dust collection system.

Differential pressure sensors review the air pressure on the filthy air and also clean air sides of the filters. The dirtier the filters are, the even more resistance they have to air going via them.

The 6-Second Trick For Best Dust Extractors

Using differential stress sensors makes a pulse-jet dust collector extra effective due to the fact that it reduces making use of pressed air. It likewise helps the cartridge filters last much longer, because the pulses of pressed air cause damage on them. Pulse-jet dust collection systems are reliable as a result of this filter cleaning.By making filters last longer, a pulse-jet collection agency is the most affordable shop dirt collection system. In horizontal dust collection system layout, the filters lay on their sides and are piled on top of each other.

In a horizontal pulse-jet dirt collector, the pulse cleansing causes dirt to be blown off the filters. Nevertheless, due to the fact that they're on top of each other, the dirt from the top filters drops on top of the others. In a vertical pulse-jet collection agency, the dirt that pulses off of the filters goes down straight down right into the hopper.

Best Dust Extractors for Dummies

When contrasting biscuits vs dowels the leading consideration is often cost. But woodworkers understand joint stamina, speed of arrangement as well as placement ease are crucial considerations. Discover what joint is best for your projects in this guide.If you concentrate on metalworking, you currently understand the importance of proper dirt collection. Not only can the metal impurities released during use a sander contaminate the air and also dirty up your shop, but they also have the potential to cause unsafe thermal events that can hurt employees and also devices.

To make sure that your dirt collection procedure is as effective as well as secure as feasible, you'll need to comprehend the best ways to operate as well as maintain these indispensable devices. At Timesavers, we produce the finest woodworking and also metalworking ending up devices in the industry.

Best Dust Extractors Fundamentals Explained

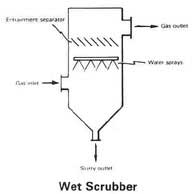

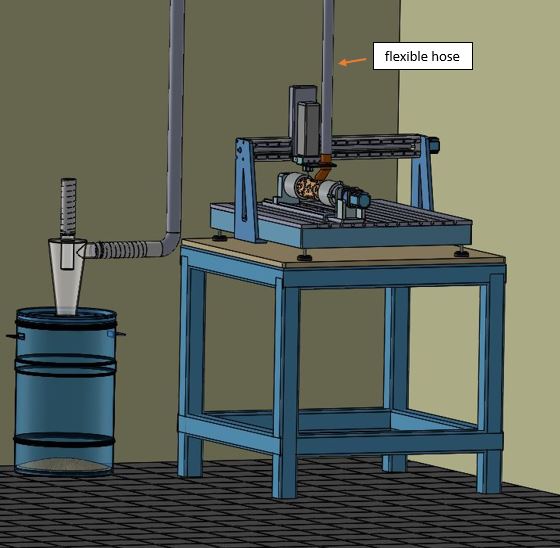

Now that you have a solid understanding of the advantages of damp dirt collection agencies, let's dive a bit deeper right into how these makers are made use of as well as preserved. To start, operators will link their commercial grinding maker to the collector through look at this website ductwork. These pipes will transfer the airalong with any kind of airborne dustinto the wet dust collector, pushing them both straight right into the water tank.

After production ends, operators will certainly make use of an inside story to by hand draw debris up as well as out of the water storage tank, leaving it got ready for the following run. Beyond these straightforward procedure actions, there are two vital factors that allow damp dirt collectors to work correctly. Best Dust Extractors. CFM (cubic feet per minute) gauges the quantity of air being relocated, and also fixed stress (Inches of Water) is the pressure of the air being relocated.

Have any kind of additional questions regarding dirt enthusiasts or steel completing in general? You can likewise call us if you would certainly such as to find out even more regarding our dust collection equipments and also just how they can increase the efficiency of your metalworking projects.

Facts About Best Dust Extractors Revealed

Dirt is an issue in any interior space. A lot of dust is additionally a flammable threat that call for special handling of the dirt.

NFPA 68 has actually considering that 2007 called for all dust to be tested to determine the explosiveness of the dust. If the dirt is not explosive after that the controls as stated above are not needed on dust enthusiasts, and on dust collectors under 8 cubic feet of the dirty side of the enclosure are excluded.

In 2015 2021 NFPA 652 mandated all business with dust collection systems to give a Dirt Hazards Evaluation DHA. This is a full analysis that consists of the dirt examination and details hazards analysis for that plant and operation. Generally done by a registered engineer as well as can set you back from $6000 to $20,000.

The Of Best Dust Extractors

How does an industrial dust collection system work? For a start, it is important to keep in mind that there are different types of dust collection systems.Various sorts of filters and various levels as well as setups of air blood circulation or suction power are used to accomplish this. Normally, the dust from the treated air will be caught or check my site visited the filter as the air comes into call with it. The dirt will certainly then drop this post right into a sediment catcher or it will be mechanically scrubbed, wiped, drunk, or pushed into the sediment collection location.

After that the air comes right into call with a series of angled pieces of metal called baffles which reduce the air down to prevent the dirt from striking the filters at a speed that would certainly damage the filters. The air is then relocated into the plenum, which is one more word for the sediment enthusiast stated over.

Report this wiki page